mechanical design of distillation column

Operation of Pressure Swing Distillation. Design and numerical analysis of s-blade axial fan for cooling of electric motors.

4 Modeling And Control Of Distillation Column In A Petroleum Process Distillation Petroleum Engineering Column

A steam injector is a typical application of the principle used to deliver cold water.

. In the oil and gas sector we design and manufacture a wide range of equipment in numerous different grades of material. Distillation or classical distillation is the process of separating the components or substances from a liquid mixture by using selective boiling and condensation. Dry distillation may involve chemical changes such as destructive distillation or cracking and is.

43 lies between the rectifying and stripping sections therefore in this case the inlet stream is between the 15th and 16th stage although this does not hold when the tray efficiency is applied as the number of stages changes. Our work in the. The main factor s involving the design of packed columns are mechanics and equipment efficiency.

On the distillation system design level various methods can be used to make continuous distillation process more energy efficient. Large columns are able to perform complete separations of. It depends on the design and operating conditions and usually varies between 04.

Distillation columns are the most widely used separation technique used in the chemical industry accounting for approximately 90 of all separations Wankat 2012. The factors related to column efficiency are liquid distribution and redistribution in order to obtain the. Typical fabrications include structural steelwork piping pressure vessels umbilicalpipe reels and tanks.

In the continuous operation the separation is. If the operator increases the reflux flow to the distillation column then the following condition will occur refer to Fig-2. The system becomes completely zeotropic and it can be separated in a distillation column.

Dry distillation is the heating of solid materials to produce gaseous products which may condense into liquids or solids. 41 436 Engineering Drawing of Drying Distillation Column Figure 410. An injector is a system of ducting and nozzles used to direct the flow of a high-pressure fluid in such a way that a lower pressure fluid is entrained in the jet and carried through a duct to a region of higher pressure.

This indicates that the percentage of propane in the bottoms product butane is held constant. Increase scale mechanical design. Among the mechanical factors one could mention liquid distributors supports pressure drop an d capacity of the column.

We have decades of experience and 420 successful system startups with multi-scale industrial distillation columns and distillation systems. Distillations in columns consist of multiple trays that each act at their own equilibrium conditions. Design and cfd modeling of a rotary device for burning of municipal solid waste.

No extra component is added into the feed or the column in order to make changes in the liquid mixture. The control of the distillation tower is such that both the pressure and bottom temperature are kept constant. This fact as well as the lack of necessary process and mechanical design know-how is a major technical barrier to be overcome to realize this regarding the potential ultimate energy saving concept in case of stand alone columns.

Mechanical Design of Drying Column 42. Selection of the proper equipment. Together with our EI and coatings group companies we also provide a complete in house solution for preassembled skid units.

Thus under practical conditions the heat exchange between steam and liquid on the plate does not reach the equilibrium state so the concept of plate efficiency energy conversion efficiency was introduced. Performance and economic analysis of solar. Project management of distillation skid fabrication to specification and tolerance Commissioning at production rates.

Sizing of each industrial column. It is a fluid-dynamic pump with no moving parts excepting a valve to control inlet flow. The design of distillation plates is important in the columns performance.

Pressure swing distillation does not utilise any additives.

Distillation Column Basic Distillation Equipment And Operation

Distillation Column Crude Oil Crude Oils

Reactive Distillation Column Distillation Fractional Distillation Column

Reflux Column With Packing Material Distillation Copper Pot Still Chemistry Lessons

Schematic Drawing Of A Segmented Tray Distillation Column Download Scientific Diagram

Distillation Distillation Piping And Instrumentation Diagram Petroleum Engineering

Typical Design Of A Staged Distillation Column With Sieve Tray And Download Scientific Diagram

Distillation Of Whiskey And Rum Fractional Distillation Distillation Chemical Engineering

Continuous Distillation Wikipedia The Free Encyclopedia Distillation Distilling Alcohol Chemical Engineering

Procedure For Continuous Distillation Column Design Panorama Consulting Engineering Inc Usa

Teg Contactors Pune Maharashtra India Id 1182724273 Petroleum Engineering Chemical Engineering Engineering Science

En Citizendium Org Images E E7 Fractional Distillation Column Schematic Png Distillation Distilling Alcohol Distilling Equipment

Distillation Tower Symbols Petroleum Engineering Piping And Instrumentation Diagram Chemical Engineering Projects

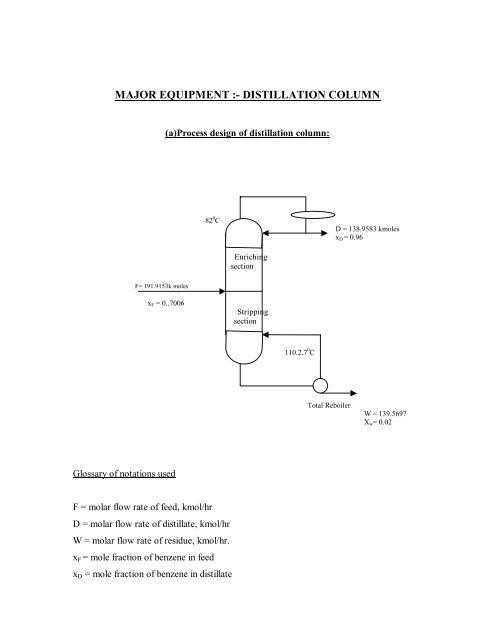

Major Equipment Distillation Column

Sieve Design Distillation Distilling Alcohol Alcohol

Engineers Guide Distillation Column Diagram

Fractionating Column Wikipedia Distillation Distillation Process Column

Pin De Anaqa En Chemical Engineering Ingenieria De Procesos Automatizacion Industrial Higiene Y Seguridad Industrial

No comments for "mechanical design of distillation column"

Post a Comment